Speculative Purchasing in this context is considering the organization does not want to keep an inventory (tax issue & storage space) and does not want to overburden projects costs.

In a custom panel-building environment, where Programable Logic Controllers (PLC) are utilized, an organization will eventually evolve to where many of the components have a general redundancy due to standardization of design. Standardizing influences efficiency as the designers know what to use by default and the technicians what to expect. Sometimes a design will require a deviation from standard material which is something to always be expected.

Common Control Panel Components

- PLC

- Terminal Blocks & accessories

- Wire Duct

- Power Supplies

- Relays

- Wire, Control

- DIN Rail

Terms

- I/O – Input/Output

- MOQ – Minimum Order Quantity

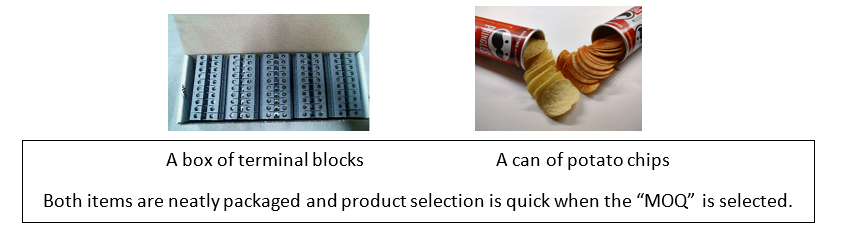

- Potato Chip Parts

Many distributors have a Minimum Order Quantity (MOQ) on small components, which I refer to as potato chip parts. Often a box of terminal blocks contains twenty-five or fifty pieces. On an project-to-order request, common MOQ components are rounded up. Sometimes, if multiple round-up orders cause a considerable surplus, an order portion will be pulled from surplus to round down or eliminate the component if a suitable quantity is available.

Another issue to consider with potato chip parts is if a design changes, then having a surplus of components in a project will reduce concern about having to place too many hasty orders to accommodate the design changes. An example of a design change is, if using a PLC, an additional I/O module may be required.

Some suppliers have no qualms about opening a box to count out a select quantity. If the component is a production standard, then continually rounding up and watching for excessive surplus does not produce problematic issues, like storage or keeping track of the extra.

On the flip side, if a project’s specifications require a non-standard component, then ordering project requirements will be preferred, though the MOQ may be supplier required.

Another issue common on potato chip parts is miscounts. A common miscounted component on panel builds is the end stop. An end stop clamps to the DIN rail to hold DIN rail mounted components, like most control panel components, in location. Position stabilized components will not eventually cause wire connection stress if gravity and vibration would induce a sliding effect on vertically mounted components. Horizontally mounted components may still slide if vibrations are severe, but the wire stress should be considerably less. Regardless of component orientation, all components should be secured on the DIN rail with end stops.

The case for rounding up is good but watching project surplus is necessary.

Another factor for rounding up other than MOQ requirements is shipping. If the component’s dimensions exceed ground shipping requirements (150 lbs. +6 ft.) taking advantage of MOQ or ordering additional will defray the overall cost for the order. An example is DIN rail. The DIN rail can be purchased in 1-meter or 2-meter lengths. The 2-meter lengths exceed common ground carrier minimums and come in packages of ten sticks. If the LTL fees for shipping is $100, then ordering two MOQs would spread the shipping costs over twenty sticks rather than ten sticks. The shipping cost will affect the project’s budget but will assist with other projects’ budget.

Cites

Terminal Blocks, Image Search, https://i.ebayimg.com/images/g/EH4AAOSwllRdiBE-/s-l400.jpg

Potato Chips, Author.